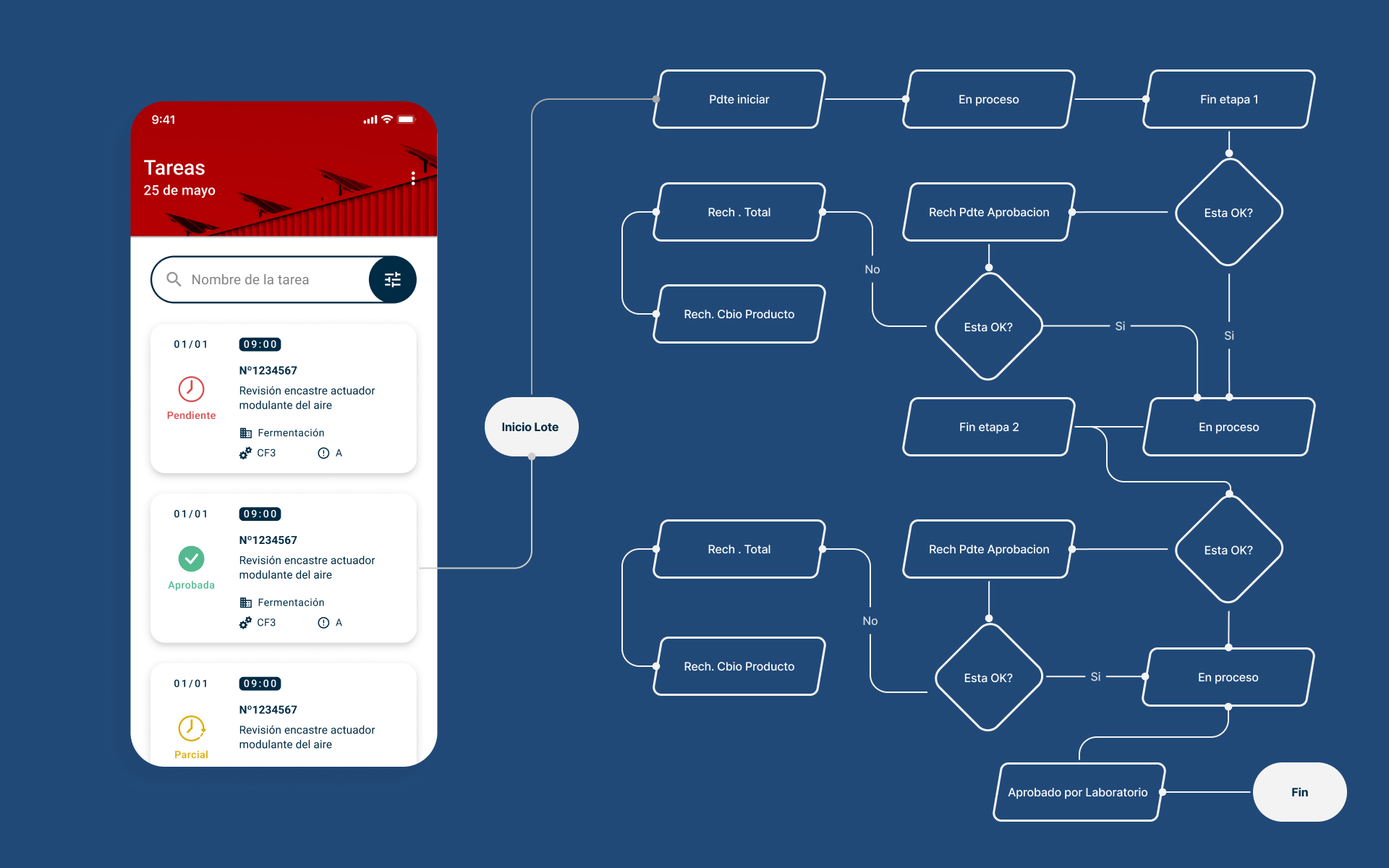

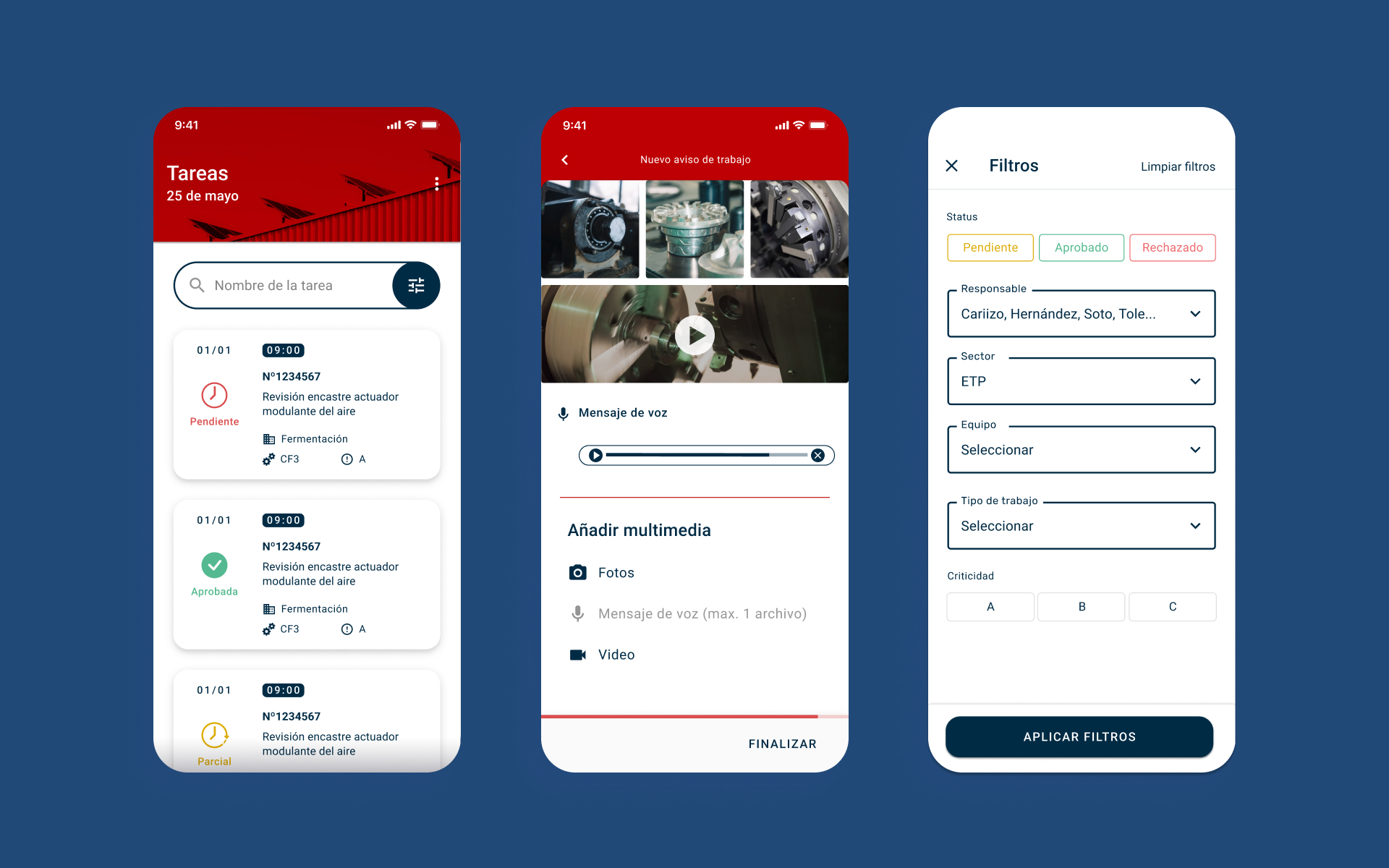

Smooth flows for maintenance and approvals

Calsa has always aimed to be a leader and benchmark in quality and service for the entire baking market. The company has grown rapidly in recent years thanks to its innovative approach of combining traditional baking techniques with advanced production technology. As the factory expanded, the directors recognised the need to develop a digital application to streamline operations, improve communication, and enhance efficiency across all departments.

My Role

I was the Product Designer and Product Strategist, responsible for understanding user needs and translating them into design requirements. I worked closely with UX designers, developers, and factory staff, running workshops and interviews to gather inputs. I coordinated teams to ensure the solution met both user needs and technical constraints.

Challenge

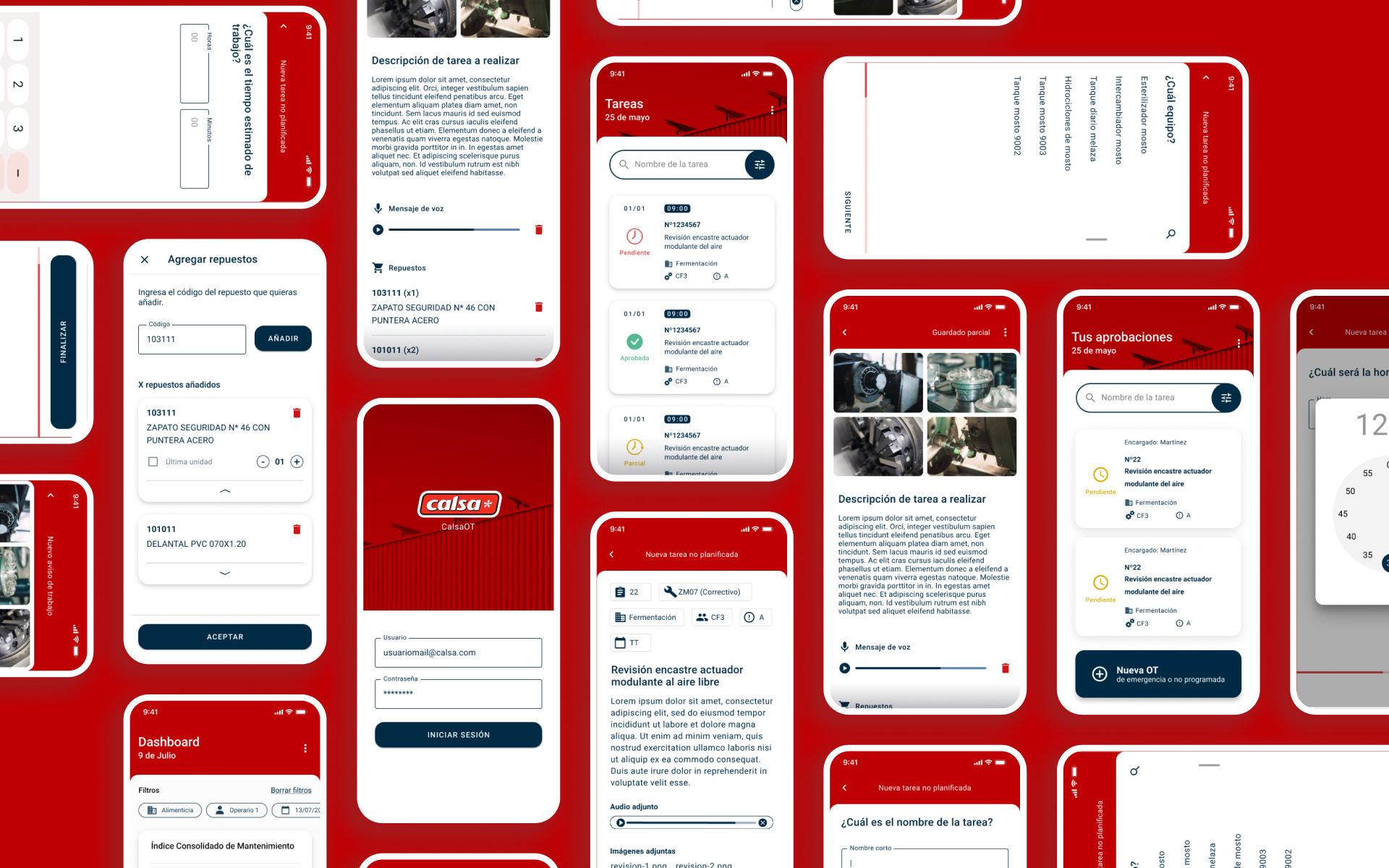

The main challenge we faced was developing an intuitive application that would transform factory workers' completely manual workflows into an efficient digital system. The goal was to enhance communication, improve real-time tracking, and ensure no data was loss. This solution had to work smoothly across 11 maintenance plants and support more than 200 active users without any hiccups.

Immersion

We started by looking closely at the factory’s daily routines to understand how tasks were done manually and the communication issues frontline workers faced. I led multiple collaborative sessions involving factory supervisors, maintenance personnel, and IT teams to uncover pain points and gather detailed user insights. These conversations were critical in aligning stakeholders around core objectives and defining the must-have features to enable a smooth digital shift.

- One-on-one interviews with key stakeholders

- On-site observation of daily processes

- Facilitated workshops with cross-functional factory teams

- Comprehensive process mapping and documentation

Challenges Faced

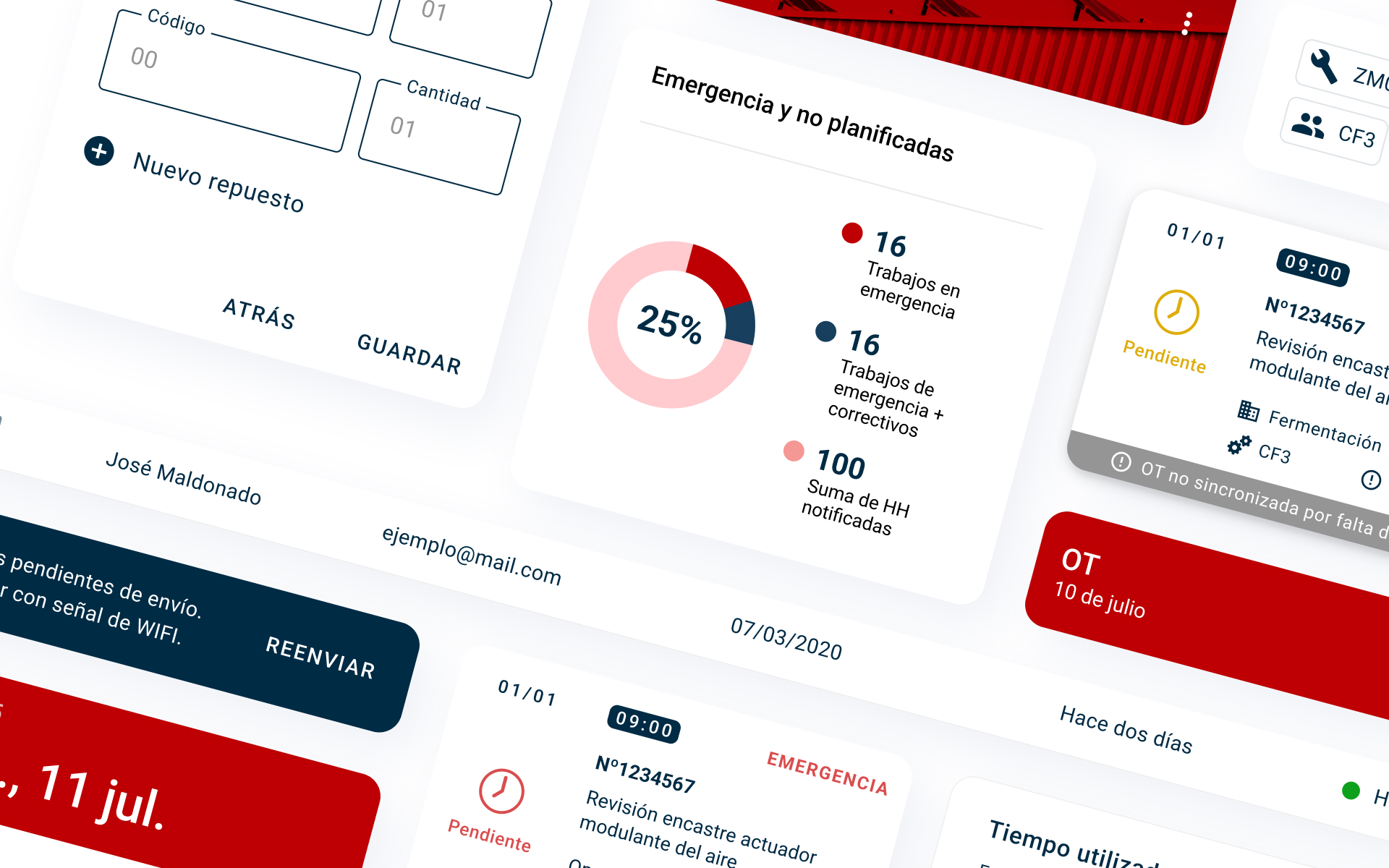

We initially tried more complex dashboards, but testing showed these were confusing for users on the factory floor. So, we simplified the interface to focus only on key tasks. Integrating with older factory systems was also tough, especially ensuring the app worked offline when connectivity was poor. We adjusted the design to handle these issues.

Product Strategy

During the product strategy phase, we set clear goals for the app: to fit smoothly into existing workflows, provide accurate real-time data, and offer an easy-to-use experience that works well in the factory environment. I conducted a competitive analysis of industrial software solutions and crafted proto-personas representing the different roles of maintenance staff and supervisors. This groundwork ensured that our feature set was strategically aligned with operational efficiency goals and the specific needs of the user using it.

User Experience

Since the factory moves fast and every decision matters, we made the app easy to use and straightforward. We kept navigation simple, the screen clean, and added clear visual cues to help workers make quick and confident choices. The app was built to run smoothly on the tablets and mobile devices workers use on the factory floor, so everyone can access it easily and without any hassle.

What I did:

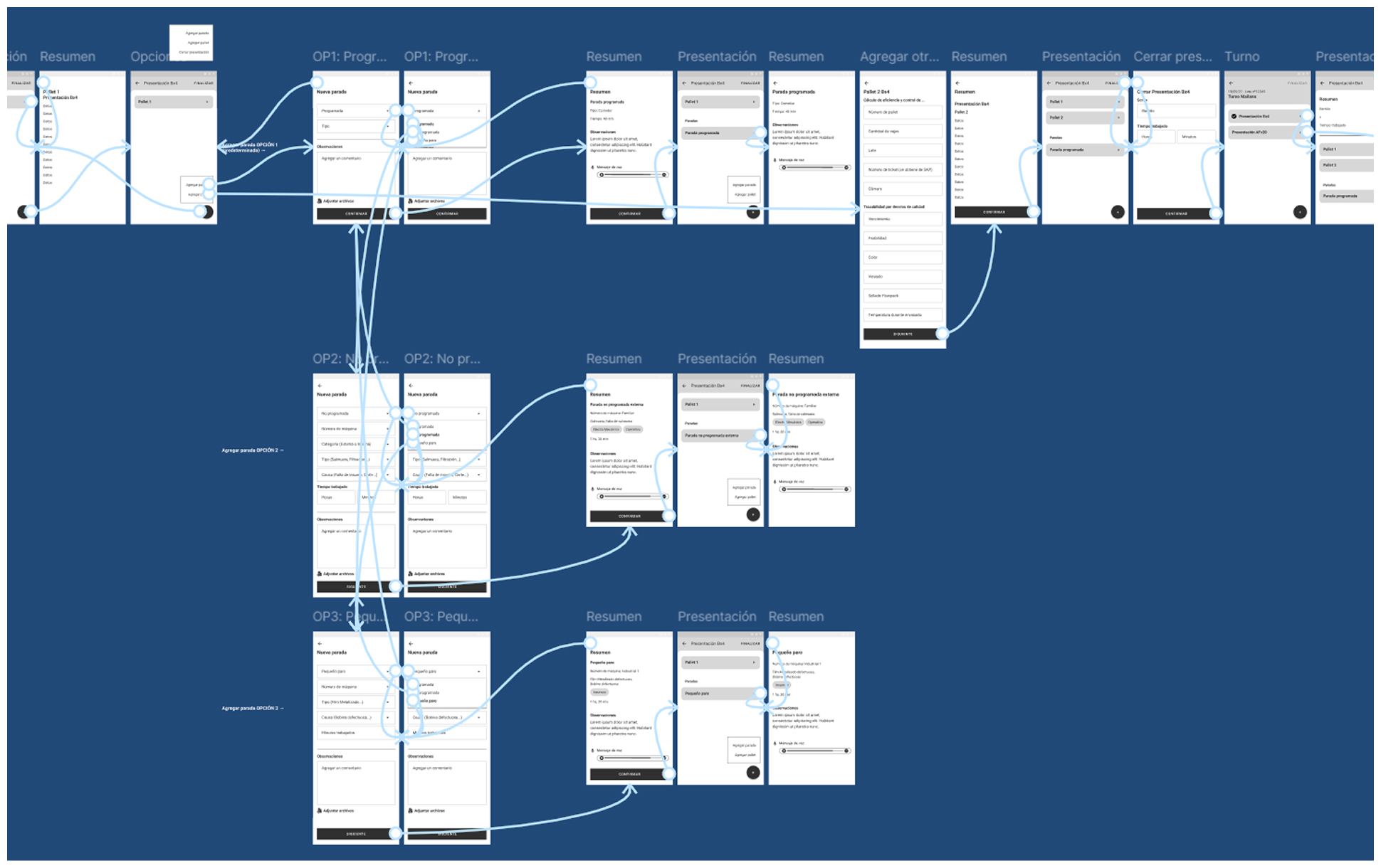

- Designed intuitive user flows

- Developed clear information architecture

- Created wireframes tailored to user needs

- Conducted one-on-one usability testing with factory workers and supervisors

- Produced detailed documentation for handover

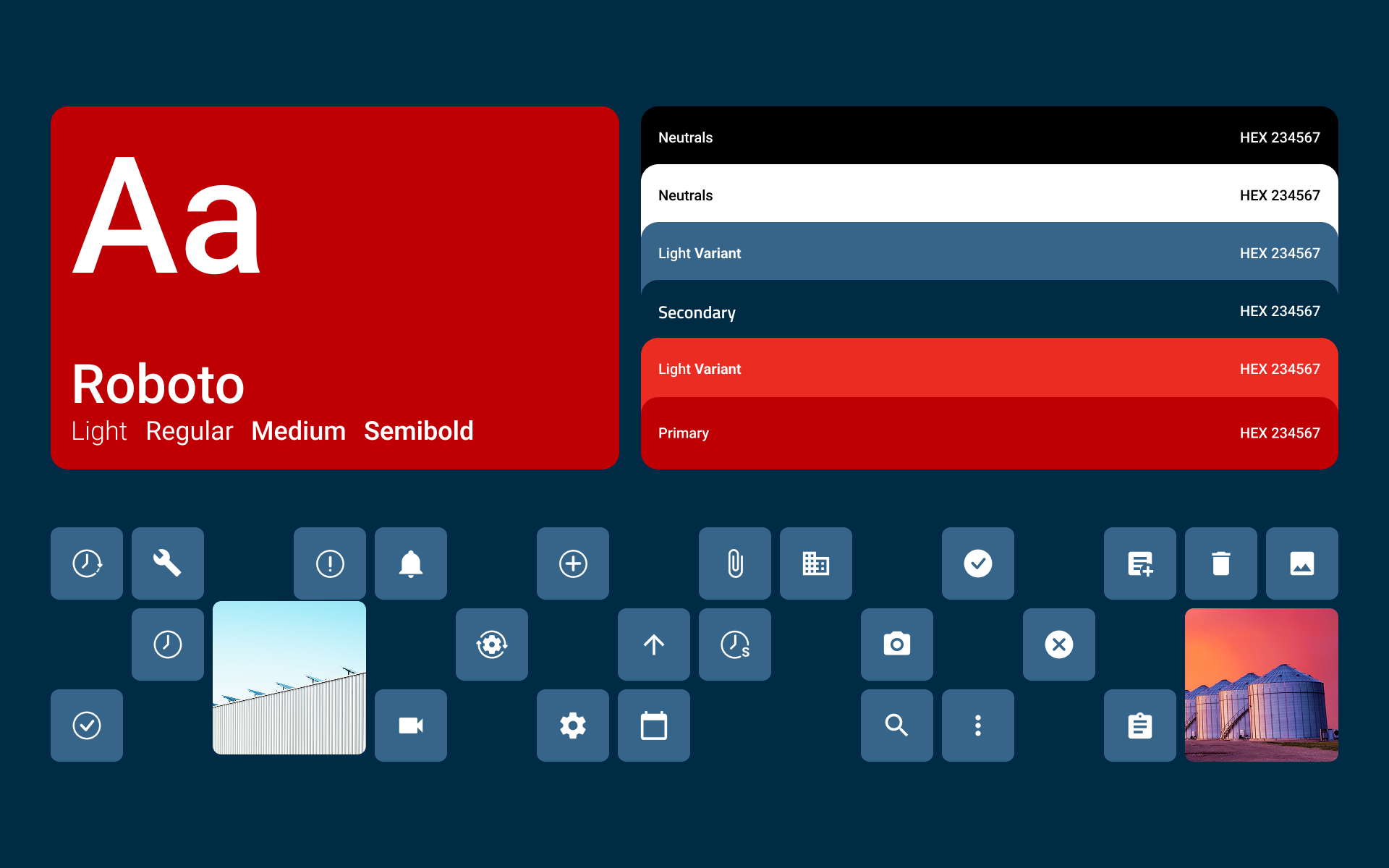

Visual Design

The interface uses bold red tones from the brand identity, paired with clean layouts and clear visual cues. This simple, distraction-free design keeps workers focused on key actions, making navigation fast, intuitive, and reliable on the factory floor.

Results

The digital app took the place of paper-based workflows with a simple system that let workers update things in real time and communicate more easily. This reduced mistakes and delays, made maintenance work run smoother, and lowered the risk of losing important data. Overall, it helped the factory keep everything running without a hitch across all the plants.

Lessons learned

I learned that keeping the design simple is crucial, especially for users who aren’t tech-savvy. Close collaboration with both technical and operational teams is important to create practical solutions. Also, ongoing user testing helped us avoid building features that didn’t add value.